|

New synthesis method for graphene using agricultural waste

|

| (Nanowerk Spotlight) The four major synthesis methods for producing graphene are: chemical vapor deposition (CVD) on metallic films, the epitaxial growth on silicon carbide, liquid exfoliation of graphite crystals, and the chemical reduction of graphene oxide. |

| Using these processes it is possible to produce high-quality and large-sized graphene in large quantities. However, they all come with drawbacks as well: the complexity of the CVD process – including high temperatures and expensive substrates – makes it not very suitable for bulk production; epitaxial growth provides a wafer-scale graphene, but silicon carbide is expensive and this process requires high temperature above 1500°C; and exfoliation or chemical reduction of graphite oxides can produce graphene in a scalable manner although the use of toxic chemical agents as well as complex processing requirements tends to complicate the scaling up of such processes. |

| In new work, researchers have now proposed an alternative way of making graphene from rice husk. They reported their findings in the March 27, 2014 online edition of Small (« Rice Husk-Derived Graphene with Nano-Sized Domains and Clean Edges ») |

|

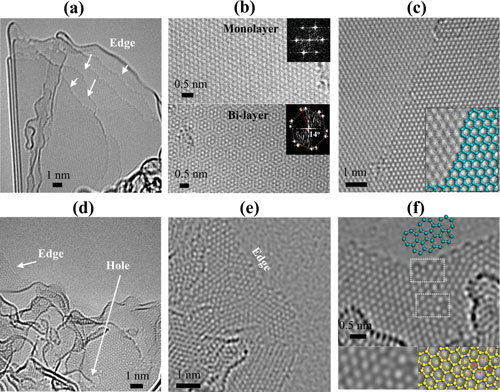

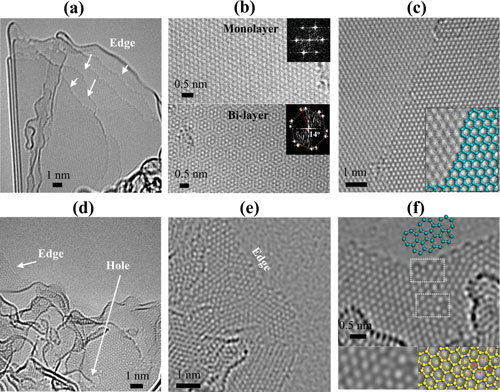

| Atomic-scale TEM images of crystalline micro-sized graphene: (a) crystalline-graphene with an exposed edge-rich structure; (b) monolayer graphene (upper) and bilayer graphene exhibiting 14° stacking rotation (bottom); (c) AA stacking exhibiting zigzag edges. Atomic-scale TEM image of corrugated graphene: (d) corrugated graphene exhibiting an edge- and nanopore-enriched structure; (e) clean edges with domains a few square nanometers; (f) localized topological defects in the edges and hexagonal carbon lattices. Note that the five- and seven-membered rings are clearly shown. (Reprinted with permission from Wiley-VCH Verlag) (click image to enlarge) |